What is Printing Service?

Printing service includes 3D modeling and 3D print production of items designed by our customers. It is particularly useful when restoring products and parts that are already discontinued, and when producing items of complex shapes that could not be constructed by conventional manufacturing methods. It provides an opportunity to turn creative ideas in one’s imagination into realities.

Our printing service covers a wide range of products from industrial parts such as sand-casting molds and cores to personal goods of metal, ceramic and plastic material.

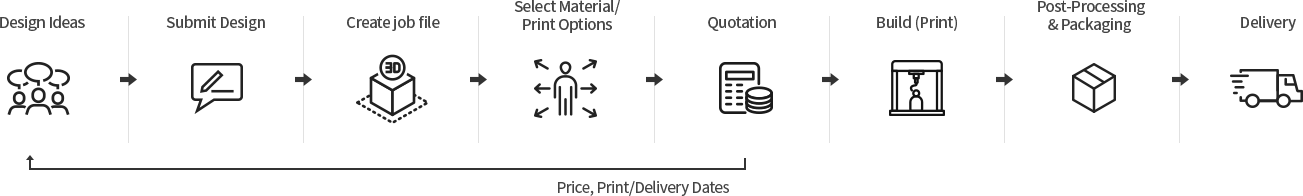

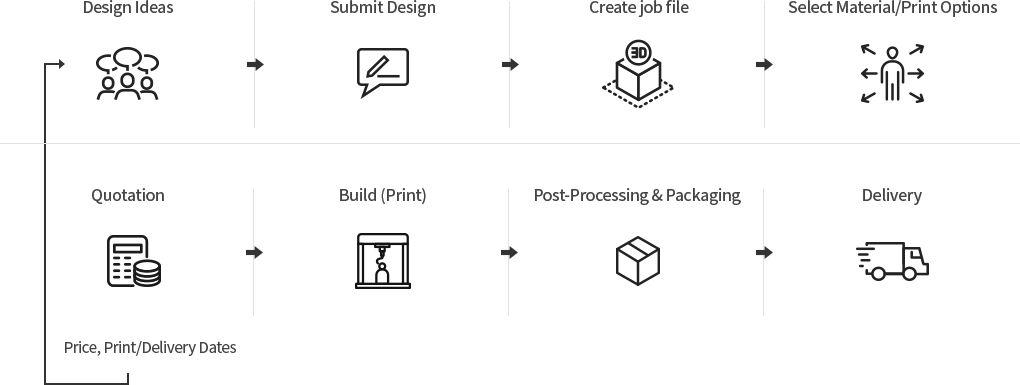

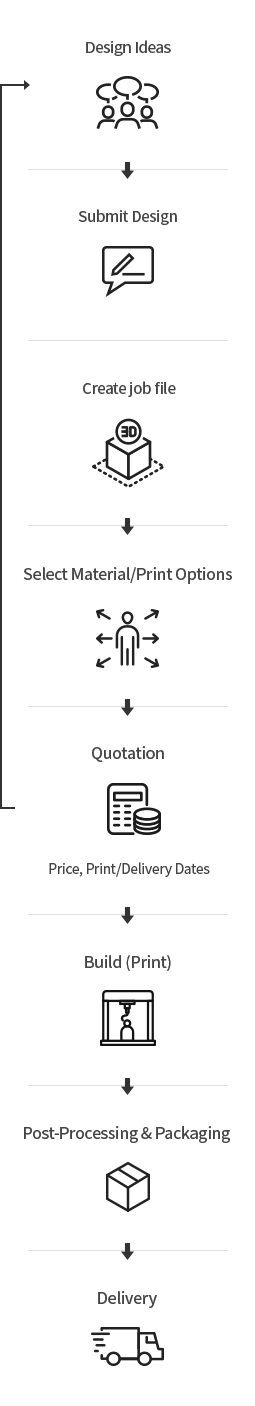

3D Printing service process

-

Casting Molds/Cores

Producing molds/cores via 3D printers saves cycle time required to carve wooden patterns and improves the quality of castings by printing mold and cores in one piece. Previously unavailable Conformal Cooling /Heating Channels can also be placed on 3D printed hot stamping and foaming molds, improving production speed and mold lifecycle, resulting in substantial savings in production costs.

-

Injection Molds/Cores

Overall productivity of injection molding largely depends on shortening the cooling phase which accounts for 60-70% of the total cycle time. 3D printed injection molds with conformal cooling channels can improve cooling efficiency by 50% and reduce the production time by 40%, leading some experts to predict that by 2025, up to 40% of all plastic products would be produced via 3D printed injection molds. However, the currently available AM methods have a few technical issues that keep printed injection molds from delivering their full financial benefits. SFS has successfully completed a pilot production of conformally-cooled injection molds using binder jetting and casting production. Our smart molds with state-of-the-art 3D cooling channels provide our customers with exceptional productivity and quality while drastically reduce the costs associated with conventional metal 3D printing.

-

Prototypes

Many small businesses and budding designers are often forced to drop new product ideas and designs simply because they can’t afford the large expenses of producing prototypes. 3D printing can deliver prototypes without incurring the extensive time and money of producing molds; therefore, help startup firms launch new products and businesses easily. Printed prototypes are available in different materials including plastic, ceramic and metals.

-

Mementos/Others

Modern manufacturing evolved around the concept of mass production, by which identical products with same design and specifications are manufactured in large volume. While most of the attention has been on bulk production, certain personal items produced in small batches and/or customized individually such as personal mementos and surgical/dental protheses have had to be hand-made and therefore have been extremely expensive. 3D printing makes available Batch Production (as opposed to Mass Production), whereby the production cost is maintained at the same level while different design and specifications are applied to each printed product. 3D printing lets us produce unique items such as “only one in the world” personal collections, custom fitted eyeglass frames and shoe insoles; and opens a whole new world where our ideas can become realities.

SFS solid freeform systems

SFS solid freeform systems